Bitumen

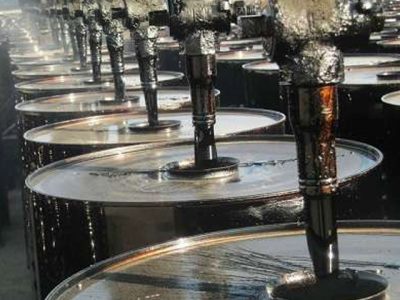

The process in which compressed air is typically blown to the vacuum subsediment at 230-260 C in a reactor. This results in different reactions (such as dehydrogenation, polymerization, oxidation) for the appropriate applications produced depending on the air blowing rate. 90 percent of the construction and maintenance of roads, 10 percent of the roof and other (duct tunnels, pipe coatings) are used. The various types are as follows:

Oil bitupeople: A mixture of hydrocarbons derived from petroleum. Black or brown, the air blowing process varies from viscous to solids by producing under vacuum (crude petroleum derivatives).

Coal tar: Coal tar is a black or dark brown sediment produced by heat treatment of coal. It's solid at room temperature.

Natural bitumen: This bitumen is extracted from mines used in many industries, including road construction, paint industry, lacquer and insulation of tanks, pipes and moulds.

Although there are many Bituperson producers, the two main refiners are Pasargad and Jay.

| Bituall Properties | ||||||

| Scale | 100-120 | 85-100 | 60-70 | 40-50 | 30-40 | Methodology |

| Density | 04/01-1/1 | 05/1-1 | 06/01-1/1 | 06/01-1/1 | 06/01-1/1 | ASTM D-7 |

| Penetration rate in C ° 25 | 100-120 | 85-100 | 60-70 | 40-50 | 30-40 | ASTM D-5 |

| Sofmy Point °c | 42-49 | 45-52 | 49-56 | 52-60 | 55-63 | ASTM D-36 |

| Sunefaction 25 °c (cm) | DK 100 | DK 100 | DK 100 | DK 100 | DK 100 | ASTM D-113 |

| Flashpoint °c | DK 250 | DK 250 | DK 250 | DK 250 | DK 250 | ASTM D-92 |

| In disulfide, the lament is wt%. | 99/5 | 99/5 | 99/5 | 99/5 | 99/5 | ASTM D-4 |

| Stain Test | Negative | Negative | Negative | Negative | Negative | A Ashto T 102 |

| Weight loss% wt. | Max. 0/2 | Max 0/2 | Max 0/2 | Max 0/2 | Max 0/2 | ASTM D-6 |

| Penetration loss by heating% | Max 20 | Max 20 | Max 20 | Max 20 | Max 20 | ASTM D-6-D5 |