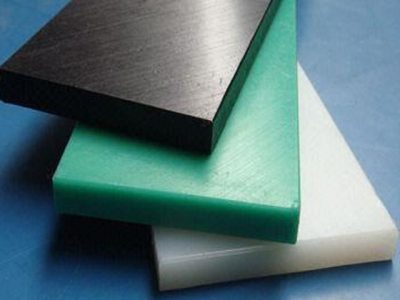

Polyethylene (HDPE)

1-Specifications

| HDPE (High Density Polyethylene) | |||

| Class | Mctor (190 C/2.16kg) | Density | |

| Film | HCH 5110a | 10 (190 °c/21.6 kg) | 0951 |

| F7000 | 0.04 | 0954 | |

| MCH 3713 | 0.1 | 0937 | |

| EX5 | 0.28 | 0949 | |

| Blow | 0035 | 0.35 | 0.953-0.959 |

| BL3 | 1.2 (190 C/5kg) | 0954 | |

| BL4 | 0.35 (190 C/5kg) | 0951 | |

| Injection | I4 | 11 (190 C/5kg) | 0954 |

| HD5030SA | 2.2 | 0950 | |

| 6040ua | 3.7 | 0.96 | |

| hı0500 | 4-6 | 0.963-0.967 | |

| 52505uv | 5 | 0952 | |

| 2200j | 5.2 | 0953 | |

| 60505uv | 5.5 | 0957 | |

| HD 62107 | 7 | 0962 | |

| I3 | 8 | 0962 | |

| HD52511 | 11 | 0952 | |

| HD60511 | 11 | 0.96 | |

| HD 5218 EA | 18 | 0952 | |

| HD52518 | 18 | 0952 | |

| HD 5620 EA | 20 | 0956 | |

| HD 6070 UA | 7 (190 C/5kg) | 0958 | |

| Pull from Mold | EX3-80s | 4 | 0954 |

| EX3-100s | 6.2 | 0948 | |

| CRP 100 Black | 0.22 (190 C/5kg) | 0957 | |

| CRP 100 N | 0.22 (190 C/5kg) | 0948 | |

| Roto | 3840ua | 4 | 0938 |

HDPE is known for its large strength-density ratio. HDPE density can be between 0.93 to 0.97 g/cm3 or 970 kg/m3. Although the density of HDPE is much less than low density polyethylene, HDPE's multi-branched, intermolecular forces and tensile strength are more powerful than LDPE. The difference is that it exceeds the difference in density by providing a higher specific strength to HDPE. It is also harder and more opaque and can withstand higher temperatures (120 ° C/248 ° F for short periods, continuously 110 ° C/230 ° F). Unlike polypropylene, high density polyethylene cannot withstand normal conditions, autoclave conditions. The lack of branching is provided by a suitable catalyst selection (e.g., Ziegler-Natta catalysts) and reaction conditions.

2-Production

High Density polyethylene (HDPE) or polyethylene high density (PEHD) is a polyethylene thermoplastic produced from petroleum. Sometimes referred to as "alkaline" or "polyethylene" when used for pipes. With high strength/density ratio, HDPE is used in the production of plastic bottles, corrosion resistant pipes, geomembrane and plastic lumber. HDPE is commonly recycled and has the number of "2" as the resin identification code.

3-Applications

HDPE is resistant to many different solvents and has a wide range of applications:

Swimming pool installation, 3d printer filament, Arena Board (Puck board), back frames, ballistic plates

Banners, bottle caps, chemical resistant pipes, coaxial cable inner insulator, food storage containers, fuel tanks for vehicles, corrosion protection for steel pipelines, personal hovercraft; Although it is very heavy for good performance, the electric and plumbing boxes

Polyethylene (Aype)

1-Specifications

| LDPE (Low Density Polyethylene) | |||

| Class | Mctor (190 C/2.16kg) | Density | |

| Movie | 2420d | 0.25 | 0923 |

| L2100TN00 | 0.3 | 0921 | |

| LTL2130 | 0.3 | 0921 | |

| LH0075 | 0.75 | 0921 | |

| 2101tn47 | 0.85 | 0921 | |

| 2102tn42 | 1.9 | 0921 | |

| 2102tx00 | 1.9 | 0921 | |

| LTM2119X | 1.9 | 0921 | |

| 2420h | 1.9 | 0924 | |

| LF-0200 | 2 | 0919 | |

| LTM2125/37 | 2.5 | 0. 921 | |

| 2004tx00 | 4.7 | 0921 | |

| LTM2447/47 | 4.7 | 0924 | |

| 2404tc47 | 4.7 | 0924 | |

| Injection | LTH1922 | 22 | 0. 919 |

The aype is defined by the 0.910-0.940 g/cm3 density range. Apart from strong oxidizing agents, it is not reactive at room temperature and some solvents cause swelling. It can withstand continuous 80 ° C and 95 ° C for a short period of time. Made in semi-transparent or opaque variations, it is very flexible and robust. The Aype has more branching than HDPE (about 2% of carbon atoms), so the inter-molecular forces (instantaneous-dipole-induced dipole extraction) are weaker, tensile strength is lower and elasticity is higher. In addition, the molecules are less tightly packaged, depending on the side branches, and are less crystalline, so the intensity is lower.

2-Production

Low density polyethylene (LDPE) is a thermoplastic made from monomers ethylene. In 1933, it was first-degree polyethylene produced by the Imperial Rady Industries (Tor), using a high-pressure process through free radical polymerization. Production uses the same method today. The EPA estimates that LDPE has recycled 5.7% of the number of recycling (4). Despite the competition from more modern polymers, aype remains an important plastic class. In 2013, the worldwide Aype market reached a level of approximately 33 billion USD.

3-Applications

LDPE is widely used in the manufacture of various types of containers, dispensing bottles, washing bottles, tubes, plastic bags for computer components and various molded laboratory equipment. The most common use is in plastic bags.

Polyethylene (LLDPE)

1-Specifications

| LLDPE (Linear Low Density Polyethylene) | |||

| Class | Mctor (190 C/2.16kg) | Density | |

| Movie | 209 AA | 0.9 | 0.92 |

| 209kj | 0.9 | 0.92 | |

| 220aa | 2.2 | 0.92 | |

| 220kj | 2.4 | 0921 | |

| 32604uv | 4 | 0932 | |

Linear low Density polyethylene (LLDPE) is a mainly linear polymer (polyethylene) with a significant number of short branches obtained by copolymerization of ethylene with long chain olefins. Linear low density polyethylene is structurally different from traditional low density polyethylene (LDPE) due to lack of long chain branching. The linearity of LLDPE stems from the different manufacturing processes of LLDPE and LDPE. In general, LLDPE is produced at lower temperatures and pressures with the copolymerization of higher alpha-olefins, such as ethylene and butane, hexene or Oxtan. The copolymerization process produces an LLDPE polymer that has a narrower molecular weight distribution than traditional LDPE and has significantly different rheological properties in combination with linear structure.

2-Production

LLDPE production is initiated by transition metal catalysts, especially Ziegler or Philips type catalyst. The actual polymerization process can be done either in the solution phase or in gas phase reactors. Usually, the butane solution phase is co-monomer, while butane and hexene are copolysed with ethylene in a gas phase reactor. LLDPE has higher tensile strength and higher impact and puncture resistance than LDPE. It's very flexible and it's growing under stress. It can be used to make finer films with better environmental stress cracking resistance. It has good resistance to chemicals. Has good electrical properties. However, it is not easy to process as LDPE, it has a lower brightness and has a narrower range for thermal insulation.

3-Applications

LLDPE has penetrated almost all traditional markets for polyethylene; Plastic bags and sheets (allows the use of comparable LDPE-less thickness), plastic packaging, stretch wrapping, bags, toys, caps, caps, pipes, buckets and containers, coating of cables, geomembranes and It is mainly used for flexible pipes. . In 2013, the world market for LLDPE reached a volume of 40 billion dollars.